Galfer USA Wave Rotors & Sintered Brake Pads

About Galfer USA

Galfer Brakes was founded in 1946 by Maffio Milesi in Barcelona, Spain. They supplied major European motorcycle manufacturers with brake pads. In 1992 one of Milesi’s sons, Giorgio Milesi, moved to Santa Barbara, California, USA and opened Galfer USA in Oxnard, California. In 2018 they moved to Carson City, Nevada. Galfer is USA is now run by Allesandro (Sandro) Milesi who continues the Family passion for racing and developing new braking products for their race teams.

With 70+ years experience in research and development of braking components they are at the leading edge in this field. Since their beginning they have been involved in high performance racing which requires the best of the best in stopping power. Giorgio Milesi is a former Moto Guzzi factory racer. Pushing motorcycles to their extreme limits is his passion and that has been the driving force behind their range of top quality products.

Maffio Milesi

From Maffio Milesi to his son Giorgio Milesi to his son Sandro Milesi, this Family has a passion for going fast and stopping fast. Their strong connection to race teams has kept them at the front of the pack.

“At Galfer we take pride in assuring the very best in our brake components, and leading edge technology to further our research and testing to bring the very best to the people who want more in a quality Performance Brake Company.” – Allesandro (Sandro) Milesi

Allesandro “Sandro” Milesi

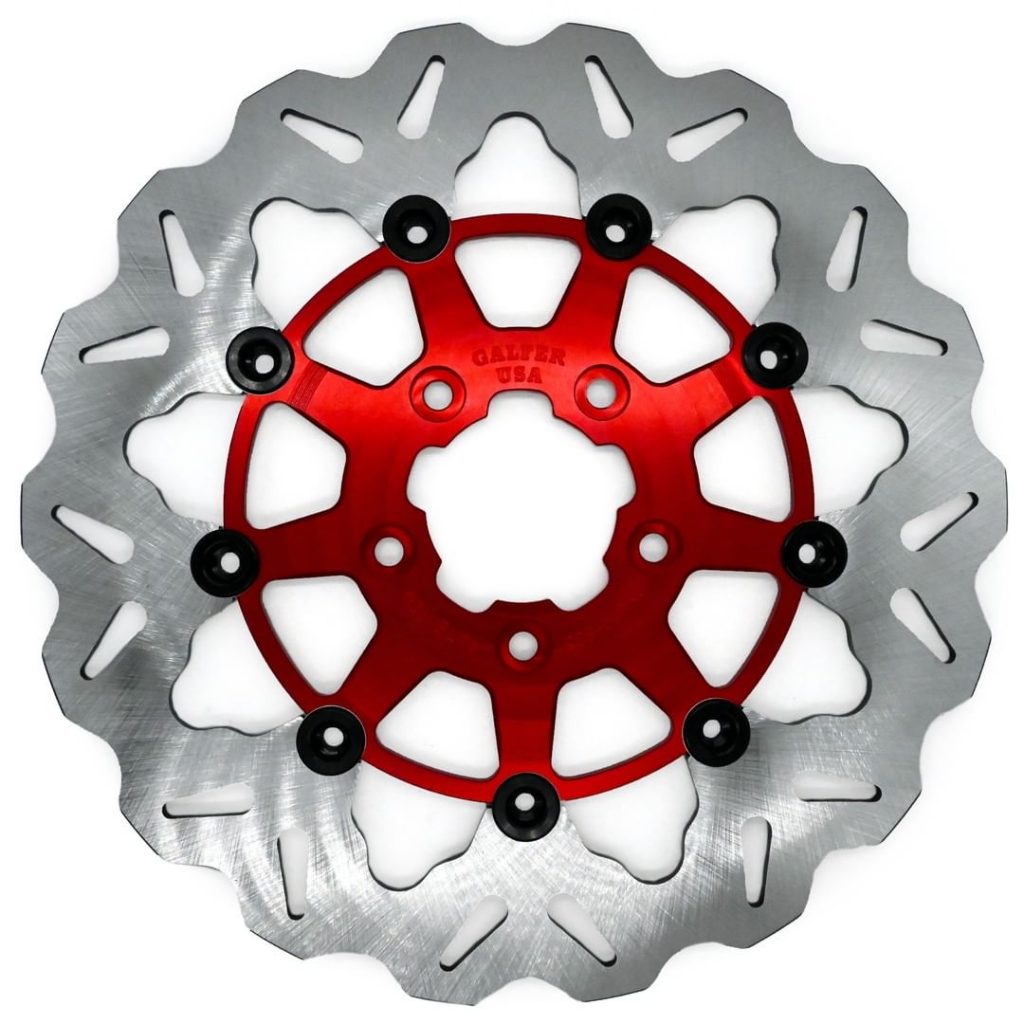

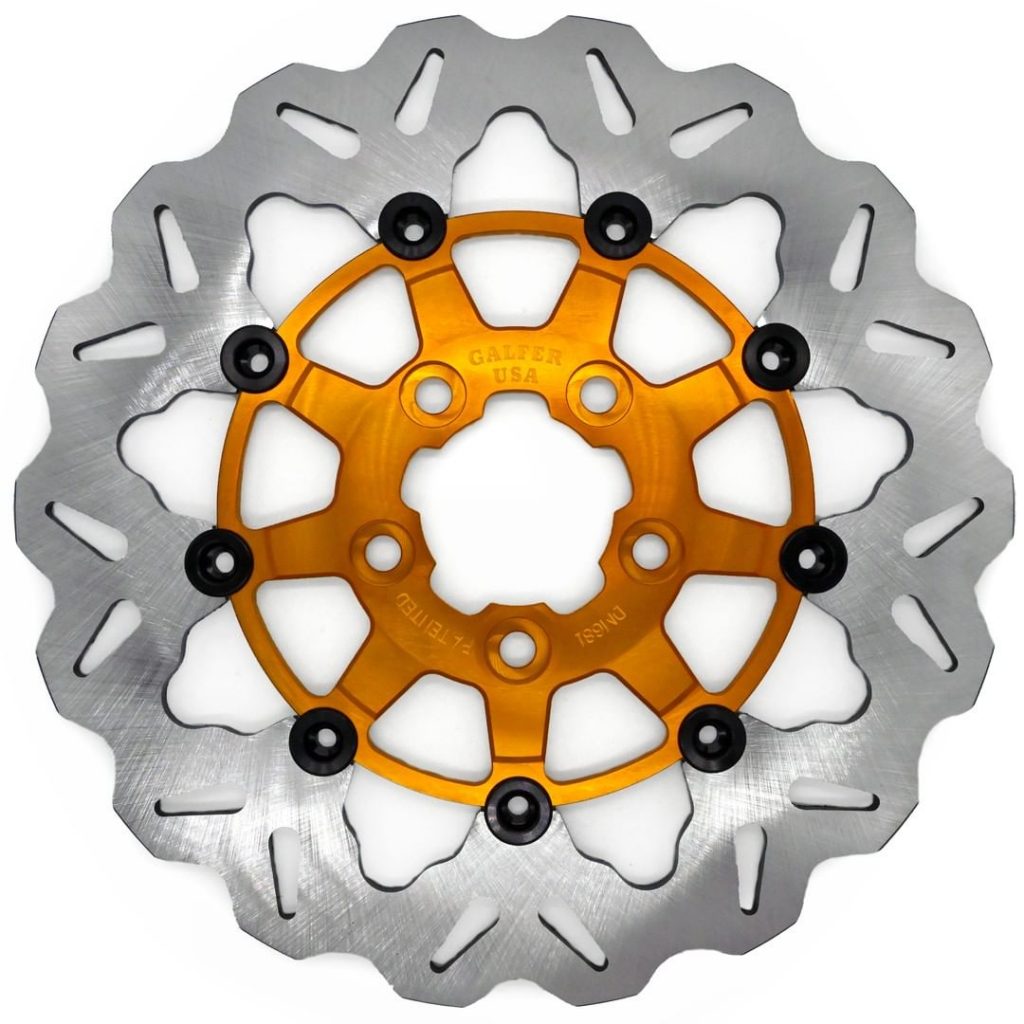

Floating WAVE Rotors

The easily recognizable WAVE design was invented by Galfer in 1991. It was designed to help remove water and mud from the rotors on trial competition motorcycles. When they began testing these they got the initial results they wanted but also discovered other benefits.

The video below was made in 2009 and explains the history and design variations of the WAVE Rotors.

The wave design alternates the pressure point on the brake pads while also providing a lighter rotor with more surface area which makes the whole system run cooler than a traditional round rotor.

This was a significant breakthrough and it launched a new generation of brake rotor technology with Galfer leading the way.

They have continued with their research, development and testing to create the amazing products we have now.

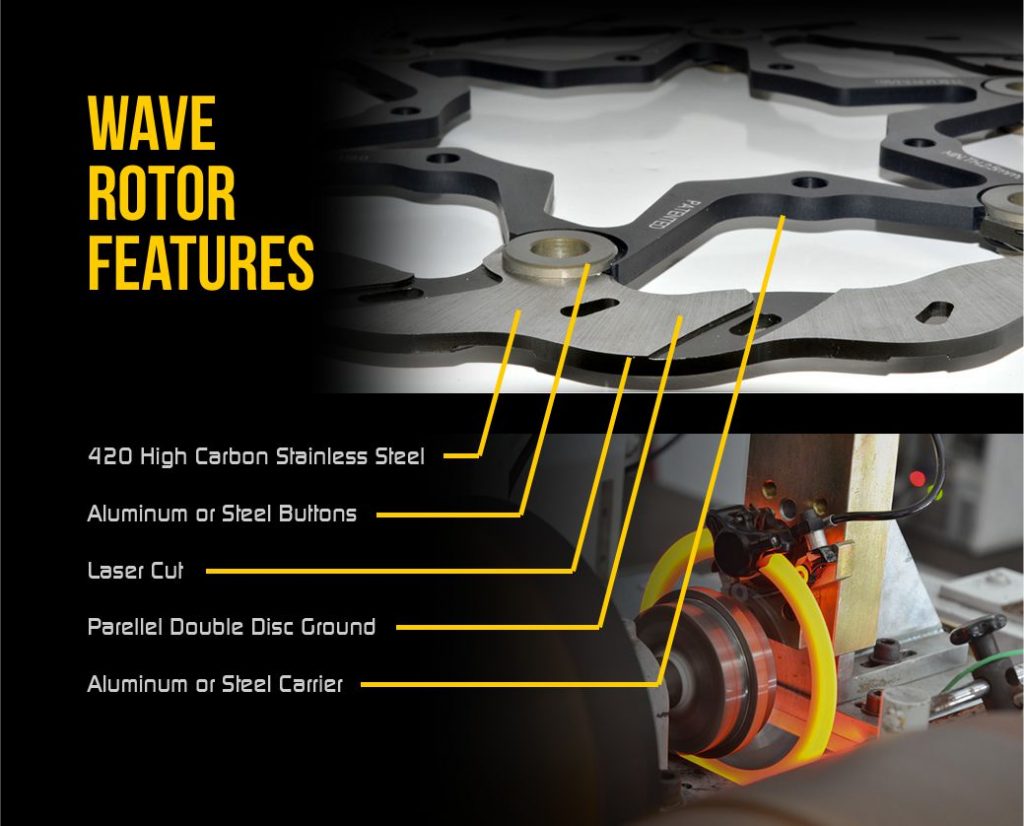

Wave© Rotor Features

- 420 High Carbon Proprietary Virgin Stainless Steel.

- Laser cut (not stamped like most others).

- Parallel Double Disc Ground for true parallel surface.

- Heat-treated for each specific application.

- Each design is CAD-CAM designed and stress analyzed.

- KBA and TUV approved.

- Aluminum relocation brackets (7075 T6 6082 T6)

- Carrier options include aluminum or stainless steel.

- Aluminum (7075-T6-6082 T6)

- Stainless Steel (AISI 420)

- Light weight rotor.

- More braking power.

- Better heat dissipation.

- Excellent resistance to corrosion.

- Less tendency to warp.

- Floating and solid mount rotor options.

- Maintains cleaner pad-disc contact surface.

- Race proven.

- Bike-specific instructions.

- 6 month warranty (when used with Galfer brake pads).

- Warranty still valid if used for racing.

WAVE© IS AN AMERICAN BRAND REGISTERED BY GALFER USA

Which Galfer USA Brake Pads Are Best for V-Twins?

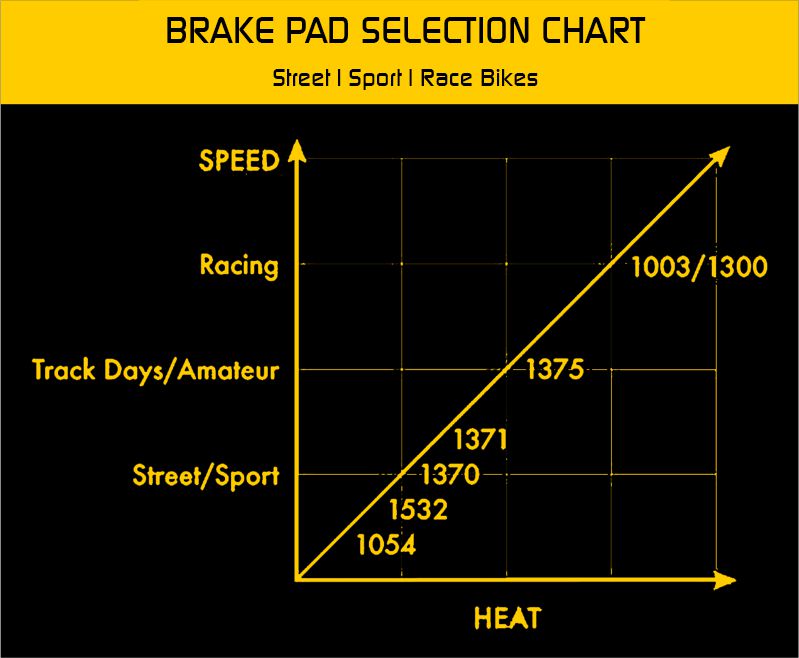

Brake pad compounds depend entirely on your riding style and type.

The faster or more aggressive of a rider you are, the stronger the brake pads you will need.

Because V-Twins are a heavier bike and we don’t know how aggressive you are when riding we highly recommend the Sintered Brake Pads.

These may be more than you need but when it comes to your braking system it is always best to have more stopping power than not enough.

Brake Pads with Part No’s between 1370 and 1397 will provide you with great stopping power .

Sintered Brake Pads by Galfer USA

The effectiveness and durability of brake pads comes down to the blend of friction material. Galfer have been refining their materials and blends for 70+ years and developed ideal blends for different applications.

When it comes to street riding on big V-Twins their best series is the Sintered Brake Pads.

Sintered brake pads are designed for more aggressive, every day riding and even race use.

- Sintered brake pads are designed for moderately aggressive use.

- These advanced ceramic brake pad composites are ready to withstand higher temperatures than regular semi-metallic carbon brake pads.

- HH friction-rated compounds deliver excellent feel and modulation.

- Sintered brake pads are developed for varying conditions.

- Sintered brake pads have good initial bite and lasting power.

Look for part numbers ending with 1370, 1371, 1380 or 1396 to suit your bike’s model & year.

We carry a selection of Sintered Brake pads to cover most Harley-Davidson and Indain Motorcycles

Stay Updated with Rollie’s

Stay up to date with the latest products and best parts and accessories info available from Rollie’s Speed Shop by joining our subscriber list.

You’ll also go into our monthly prize draws to win cool Rollie’s merchandise. It doesn’t get any easier than that 😉